RHL Associates LLC

Authorized Process Technology® Distributor.

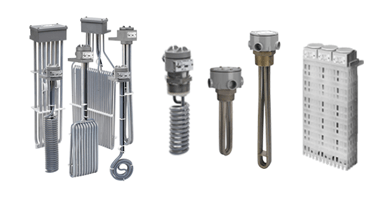

- Electric Immersion Heaters

- Heat & Cooling Coils

- DC Power Supplies

- Temperature Controls

- In-Line Water Heaters

- Chemical / Solvent Heaters

- And more.....

Process Technology® HX Series Spiral Fluoropolymer (PTFE) heaters

Compatible with virtually any chemistry

- Excellent chemical resistance to aggressive acids! Spiral element. Low watt density. Built-in thermal protector and grounded element. Fluoropolymer (PTFE) sleeved 304 stainless elements inert to most solutions up to 212°F (100°C). Corrosion-resistant head. Single phase. 9782738100 watts, 120-480 volts.

Applications

Surface Finishing

Process Technology® HXL Series Spiral L-Shaped Fluoropolymer (PTFE) heaters

Compatible with virtually any chemistry

- Excellent chemical resistance to aggressive acids! Inert to most solutions with a corrosion-resistant head. Low watt density. Built-in thermal protector and grounded element. Spiral, low profile, bottom heater. Fluoropolymer (PTFE) sleeved 304 stainless elements inert to most solutions up to 212°F (100°C). 9782738100 watts, 120-480 volts.

Applications

- Surface Finishing

Process Technology® HXF Series Low Profile Fluoropolymer (PTFE) heaters

Compatible with virtually any chemistry

- Excellent chemical resistance to aggressive acids! Inert to most solutions with a corrosion-resistant head. Low watt density. Built-in thermal protector and grounded element. Heats up to 212°F (100°C). 9782738100 watts, 120-480 Volts.

Applications

- Surface Finishing

Process Technology® HXFL Series Low Profile L-Shaped Fluoropolymer (PTFE) heaters

Compatible with virtually any chemistry

- Excellent chemical resistance to aggressive acids! Low profile, bottom design. Inert to most solutions with a corrosion reisistant head. Low watt density. Built-in thermal protector and grounded element. Corrosion-resistant head. Heats up to 212°F (100°C). 9782738100 watts, 120-480 volts.

Applications

- Surface Finishing

Process Technology® HXO Series Fluoropolymer (PTFE) heaters

Compatible with virtually any chemistry

- Excellent chemical resistance to aggressive acids! Inert to most solutions with a corrosion-resistant head. Low watt density. Built-in thermal protector and grounded element. Fluoropolymer (PTFE) sleeved 304 stainless elements inert to most solutions up to 212°F (100°C). 9782738100 watts, 120-480 volts.

Applications

- Surface Finishing

Process Technology® 3HXO Series Three Element Fluoropolymer (PTFE) heaters

Compatible with virtually any chemistry

- Excellent chemical resistance to aggressive acids! Inert to most solutions with a corrosion-resistant head. Low watt density. Built-in thermal protector and grounded element. 3 element, O shaped fluoropolymer (PTFE) sleeved 304 stainless elements inert to most solutions up to 212°F (100°C). 1500-18000 watts, 120-480 volts.

Applications

- Surface Finishing

Process Technology® 3HXOL Series Three Element L-Shaped Fluoropolymer (PTFE) heaters

Compatible with virtually any chemistry

- Excellent chemical resistance to aggressive acids! Inert to most solutions with a corrosion-resistant head. Low watt density. Built-in thermal protector and grounded element. 3 element, bottom heater, fluoropolymer (PTFE) sleeved 304 stainless elements. Heats up to 212°F (100°C). 9782738100 watts, 9782738100 volts.

Applications

- Surface Finishing

Process Technology® 3HX Series Three Element Fluoropolymer (PTFE) heaters

Compatible with virtually any chemistry

- Excellent chemical resistance to aggressive acids! 3 element. Low watt density. Built-in thermal protector and grounded element. Fluoropolymer (PTFE) sleeved 304 stainless elements inert to most solutions up to 212°F (100°C). Corrosion-resistant head. Three phase. 1000-6000 watts, 120-480 volts.

Applications

- Anodizing

- Precious Metal Deposition

- Electrochemical Deposition

- Water Treatment

- Electropolishing

Process Technology® 9HX Series Nine Element Fluoropolymer (PTFE) heaters

Compatible with virtually any chemistry

- Excellent chemical resistance to aggressive acids! 9 element. Low watt density. Built-in thermal protector and grounded element. Fluoropolymer (PTFE) sleeved 304 stainless elements inert to most solutions up to 212°F (100°C). Corrosion-resistant head. Three phase. 9782738100 watts, 120-480 volts.

Applications

- Anodizing

- Precious Metal Deposition

- Electrochemical Deposition

- Water Treatment

- Electropolishing

Process Technology® HXRL Series Flexible Riser Low Profile Fluoropolymer (PTFE) heaters

Compatible with virtually any chemistry

- Flexible riser, low watt density, bottom heater has Fluoropolymer (PTFE) sleeved 304 stainless elements inert to most solutions up to 212°F (100°C) and a a chemical resistance to aggressive acids! Grounded internal metal element and built-in thermal protector. Resettable P3 J-type thermocouple standard. Single phase. 1000-6000 watts, 120-480 volts.

Applications

- Surface Finishing

- Anodizing

- Precious Metal Deposition

- General Metal Finishing

Process Technology ® HXOL Series Flexible Riser Fluoropolymer (PTFE) heater

Compatible with virtually any chemistry

- Excellent chemical resistance to aggressive acids! Inert to most solutions with a corrosion-resistant head. Low watt density. Built-in thermal protector and grounded element. Fluoropolymer (PTFE) sleeved 304 stainless elements inert to most solutions up to 212°F (100°C). 1000-6000 watts, 120-480 volts (600 volts on 4500 watts or lower only)

Applications

- Chemical Heating

- Anodizing

- Surface Finishing

Process Technology® HXSL Series Flexible Riser Fluoropolymer (PTFE) heaters

Compatible with virtually any chemistry

Custom, low watt density, flexible riser bottom heater has heavy-wall fluoropolymer (PTFE) sleeved 304 stainless elements inert to most solutions up to 212°F (100°C) and a chemical resistance to aggressive acids! Grounded internal metal element and built-in thermal protector. Resettable P3 protector. Corrosion-resistant head. Single phase. 1000-6000 watts, 120-480 volts.

Applications

- Surface Finishing

- Anodizing

- Precious Metal Deposition

- General Metal Finishing

Process Technology® 6HX Series Flexible Riser Fluoropolymer (PTFE) heaters

Compatible with virtually any chemistry

- Excellent chemical resistance to aggressive acids! 6 element. Low watt density. Built-in thermal protector and grounded element. Fluoropolymer (PTFE) sleeved 304 stainless elements inert to most solutions up to 212°F (100°C). Corrosion-resistant head. Three phase. 9782738100 watts, 120-480 volts.

Applications

- Anodizing

- Precious Metal Deposition

- Electrochemical Deposition

- Water Treatment

- Electropolishing

Process Technology® X Series Coil Fluoropolymer (PTFE) heaters

Robust Design

- Eliminates stray currents in tanks. Excellent chemical compatibility and rugged design for your heating or cooling application. All wetted parts of fluoropolymer (FEP, PFA or PTFE) construction with a heavy duty CPVC mounting bracket. Standard coils are FEP and rated up to 30 PSI steam service. PFA coils are available for steam service up to 60 PSI. 10 PSI minimum steam pressure required for operation. Heavy wall tubing improves circulations and reduces pressure drop. Heavy duty CPVC mounting bracket and 1/8-inch thick perforated guard helps protect the coil from damage. Integral inlet/outlet connections reduce potential for leaks. 10 PSI minimum steam pressure required for operation.

- Vacuum breakers recommended for fluoropolymer heat coil steam heating installations.

Process Technology® U Series Coil

For low surface area requirements

- Designed for the high demands of corrosive chemical heating or cooling requiring minimal recovery time. Every inch of coil surface is active exchange area. Available in heavy wall, 20-gauge metal tubing available in steel, 316 stainless steel and titanium.

Process Technology® H Series Coil

Engineered for you

- Space saving helical design for use in heating or cooling applications, alkaline or acid solutions and rinse tanks with low flow (laminar flow) rates. Check solution guide or consult with your chemical supplier for proper sheath material. Available in multi-layer coils with heavy wall, 18-gauge metal tubing available in steel, 316 stainless steel and titanium.

Process Technology® G Series Coil

Durable, low-profile design

- Designed for the high demands of corrosive chemical heating or cooling for larger tanks and greater efficiency. Durable, low profile design. Every inch of coil surface is active exchange area. Check solution guide or consult with your chemical supplier for proper sheath material. Heavy wall, 20-gauge metal tubing available in steel, 316 stainless steel and titanium.

Process Technology® SP Series Coil

SP (Serpentine) Series, Immersion Coil

- Designed for the high demands of corrosive chemical heating or cooling requiring minimal recovery time. Every inch of coil surface is active exchange area. Check solution guide or consult with your chemical supplier for proper sheath material. Efficient, long-life design. Heavy wall, 20-gauge metal tubing available in steel, 316 stainless steel and titanium.

Process Technology® MOTS Triple

Durable, efficient chemical heater

- For use in most aqueous alkaline solutions, plating and phosphate tanks. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Available in Steel, 304 Stainless Steel, 316 Stainless Steel, and Titanium. Three phase. Heats up to 180°F (82°C). 3000-36000 watts. 240-480 volts.

Applications

- Surface Finishing

- For use in most aqueous alkaline solutions, plating and phosphate tanks.

Process Technology® HMOTS Triple - Derated

For concentrated alkaline or caustic solutions

- Low watt density, three phase, durable, efficient metal heater for concentrated alkaline or caustic solutions. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Available in Steel, 304 Stainless Steel, 316 Stainless Steel, and Titanium. Three phase. Heats up to 180°F (82°C). 1500-18000 watts. 120-480 volts.Low watt density, three phase, durable, efficient metal heater for concentrated alkaline or caustic solutions

Process Technology® MOTS Triple Deep Tank

Durable, efficient chemical heater

- Deep tank heater available in Steel, 304 Stainless Steel, 316 Stainless Steel, and Titanium. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Three phase. Heats up to 180°F (82°C). Single or three phase. 1800-54000 watts, 9782738100 volts.Deep tank heater available in Steel, 304 Stainless Steel, 316 Stainless Steel, and Titanium

Process Technology® MOTS Single - Bottom

Durable, efficient chemical heater

- Bottom style, L-shaped MOTS heater with heavy wall metal sheaths available in steel, 304 stainless steel, 316 stainless steel and titanium. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Heats up to 180°F (82°C). Single or three phase. 1000-12000 watts, 120-480 volts.

Process Technology® MOTS Triple Vertical Derated

Durable, efficient chemical heater

- Derated Three Phase. L-shaped, vertical MOTS heater with heavy wall metal sheaths available in steel, 304 stainless steel, 316 stainless steel and titanium. Heats up to 180°F (82°C). 3,000-36,000 watts, 9782738100 volts.

Process Technology® MOTS Triple L-shaped

Durable, efficient chemical heater

- Bottom style, L-shaped MOTS heater with heavy wall metal sheaths available in steel, 304 stainless steel, 316 stainless steel and titanium. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Three phase. Heats up to 180°F (82°C). Three phase. 9782738100 watts, 9782738100 volts.

Process Technology® 2T-T2T Series - Screwplug

Durable, efficient chemical heater

- Durable, efficient, chemical, screwplug heater in 316 stainless steel or titanium elements for use in most aqueous alkaline solutions and rinse tanks. 2 inch. Heats up to 180°F (82°C). 9782738100 watts, 9782738100 volts.

Process Technology® T Series Screwplug

Durable, efficient chemical heater

- Screwplug heater in 304 stainless, 316 stainless steel or titanium elements for use in most aqueous alkaline solutions and plating and phosphate tanks. Grounded construction. Heats up to 180°F (82°C). 1000-12000 watts, 120-480 volts.

Process Technology® 3HS Series - Tubular

Durable, efficient chemical heater

- Over the side, durable, efficient, 3 element, tubular chemical heater. Available in Steel, 304 Stainless Steel, 316 Stainless Steel, and Titanium. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Three phase. Heats up to 180°F (82°C). Three phase. 9782738100 watts, 9782738100 volts.

Process Technology® 6HS Series - Tubular

Durable, efficient chemical heater

- Over the side, durable, efficient, 6 element, tubular chemical heater. Heavy wall metal sheaths available in 316 stainless steel. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Corrosion-resistant head. Three phase. Heats up to 180°F (82°C). 9782738100 watts, 9782738100 volts.

Process Technology FLS Series Flanged

Durable, efficient chemical heater

- Heavy wall metal sheaths available in 316 stainless steel and titanium. 316 Stainless Steel standard with metal explosion resistant M2 terminal enclosure. Check solution recommendation chart with your chemical supplier for proper sheath material selection. 3", 5" and 6" flange sizes. Heats up to 180°F (82°C). 9782738100 watts, 9782738100 volts

Process Technology® MOTS Single

Lab or small tank heater

- Lab or small tank, metal over the side heating solution available in 304 stainless steel, 316 stainless steel or titanium provide protection from most chemistries. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Heats up to 180°F (82°C). Single or three phase. 1000-12000 watts, 120-480 volts.

Process Technology® MOTS Single - Derated

For concentrated alkaline or caustic solutions

- Low watt density, derated, durable, efficient metal heater for concentrated alkaline or caustic solutions. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Available in Steel, 304 Stainless Steel, 316 Stainless Steel, and Titanium. Heats up to 180°F (82°C). Single or three phase. 9782738100 watts, 120-480 volts.

Process Technology® MOTS Single DAS, Phosphate

Designed for phosphate coating applications

- For use in iron, zinc and manganese phosphate tanks. Check solution recommendation chart with your chemical supplier for proper sheath material selection. P4 protector for solutions up to 230°F (110°C). Single or three phase. 1000-10000 watts, 120-480 volts.

Process Technology® 5T-T5T Series - Screwplug

Durable, efficient chemical heater

- Durable, efficient, chemical, screwplug heater in 316 stainless steel or titanium elements for use in most aqueous alkaline solutions and rinse tanks. 2 1/2 inch. Heats up to 180°F (82°C). 9782738100 watts, 9782738100 volts.

Process Technology® 9HS Series - Tubular

Durable, efficient chemical heater

- Over the side, durable, efficient, 9 element, tubular chemical heater. Heavy wall metal sheaths available in 316 stainless steel. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Corrosion-resistant head. Three phase. Heats up to 180°F (82°C). Three phase. 9782738100 watts, 9782738100 volts.

Process Technology® A Series - Aquaculture

Compact Aquaculture size. 316 stainless steel for fresh water or titanium for salt water applications Available in Over the Side, L Shaped and Screwplug styles. Vapor resistant, flame retardant polypropylene terminal enclosure with 8.5 flexible cord on 1000 watt, 120-240 volt and 1800-2500 watt, 240 volt heaters. 3 foot wire and conduit on 1800-2500 watt, 120 volt and all 9782738100 watt heaters. P1 thermal protector standard for solutions up to 180°F (82°C). 1000-6000 watts. 120-240 volts.

Applications

- Aquaculture

- Lab Applications

Related Products

Process Technology® B Series - Small Tank

- Lab or small tank, metal over the side heating solution available in 304 stainless steel, 316 stainless steel or titanium provide protection from most chemistries. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Heats up to 180°F (82°C). Single phase. 9782738100 watts, 120-240 volts. Custom configurations available.

Process Technology® Easyplug™ - Aquaculture

- Quick plug in system for aquaculture applications.316 stainless steel for fresh water or titanium for salt water applications. Watt densities up to 40 watts/square inch (6.5 w/cm²). Vapor resistant, flame retardant polypropylene terminal enclosure with 8.5 flexible cord/plug. 1000 watt, 120 or 240 volt. or 1800 watt, 240 volts. P1 thermal protector standard for solutions up to 180°F (82°C)

Application

- Aquaculture

- Small Lab Heater

Process Technology® QM Series Heater Element

- Compatible with many aggressive chemistries. Heavy wall metal element, quartz sheath and polypropylene guards (sold independently for assembly). For use in most aqueous acidic plating solutions and pickling tanks. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Single phase. Heats up to 180°F (82°C). 9782738100 watts, 120-480 volts.

Process Technology® QM Series Quartz Sheath

For acidic solutions

- Compatible with many aggressive chemistries. Heavy wall metal element, quartz sheath and polypropylene guards (sold independently for assembly). For use in most aqueous acidic plating solutions and pickling tanks. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Single phase. Heats up to 180°F (82°C). 9782738100 watts, 120-480 volts.

Process Technology® V Series - Varipower

Lab or small tank heater

- V Series or Varipower. Excellent for laboratory and small tank applications. For use in most aqueous alkaline solutions, plating and phosphate tanks. Check solution recommendation chart with your chemical supplier for proper sheath material selection. Available in 316 stainless steel, titanium or fluoropolymer sheath to provide protection from most chemistries. Single phase. Heats up to 212°F (100°C). 100-1000 watts, 120-240 volts.

Process Technology® HX Series Guard

Electric Immersion Heater Guards

- Protect your electric immersion heater investment. For use in most aqueous acidic plating solutions and pickling tanks. Check the solution recommendation chart with your chemical supplier for proper sheath material selection. Universal mounting flange. Reduces plate-out, improves fluid circulation around elements. Solutions up to 180°F (82°C). Available in Polypro or PFA.

Process Technology®

Diamond Series

Powerful Small Package!

The Dynatronix by Process Technology - Diamond DHP Power Series is designed to be a direct replacement for traditional SCR rectifiers, the Diamond Series offers many high current models, with better regulation and a much smaller footprint than an SCR rectifier. With the ability to link multiple modules in Series or Parallel, the Diamond Series can meet your high-current requirements with ease! DC, Air cooled, 200-3 amps, 12-80 volts, 36,000 watts

Dynatronix by Process Technology®

Microstar DuP/DuPR Series

Packed with features

The Dynatronix by Process Technology - MicroStar Series is one of the most flexible product lines we offer. Designed to be used in almost any general metal finishing application. Simple to use, yet packed with features. Models in the 0.1 to 3 ampere output range are ideally suited for laboratory or R&D applications. DC, High Frequency Pulse (HFP) or Pulse Reverse, Air cooled, Benchtop, 5-250 amp avr, 20-40 volts, 5,000 watts

Dynatronix by Process Technology®

Microstar CRS Series 300A

Packed with features

The Dynatronix by Process Technology - MicroStar CRS Series - 10 to 300 amperes - is one of the most flexible product lines we offer. Multiple options for control interfaces. Small package size: switch mode technology. Rugged, environmentally-sealed, powder-coated enclosure. Designed to be used in almost any general metal finishing application. Simple to use, yet packed with features. DC, Air cooled, Benchtop, 10-300 amps, 12-48 volt, 3,600 watts

Dynatronix by Process Technology®

Microstar CRS Series 1000A

Packed with features

The Dynatronix by Process Technology - MicroStar CRS Series - DC - 500 to 1000 amperes - is one of the most flexible product lines we offer. Rugged, environmentally-sealed, powder-coated enclosure. Small package size: switch mode technology. Designed to be used in almost any general metal finishing application. Simple to use, yet packed with features. DC, Air cooled, Benchtop, 5-250 amps avr, 20-40 volts, 5,000 watts

Dynatronix by Process Technology®

DTX-2400 Series

Switch mode technology

The Dynatronix by Process Technology DTX-2400 power convertor is the latest generation of DC power supplies for precision plating with features and benefits that set it apart from the current products in the market today. Utilizing switch mode technology to pack 2400 watts of output power into a compact footprint for the most efficient use of space with an environmentally sealed enclosure. Truly a powerhouse that packs a punch! DC, 200Hz, Air cooled, Benchtop 10-100 amps, 0-100 volts, 2400 watts, switch-mode technology

Applications

- Precious Metal Deposition

- Anodizing

- Electro-Forming

- Electro-Polishing

Dynatronix by Process Technology®

DTX-6000 Series

New high-performance power supply

The high-performance DTX-6000 Dynatronix by Process Technology Power Supply will bring your process to the next level, delivering accurate, ultra-low ripple DC power.

Inside high-efficiency silicon carbide (SiC) components and synchronous rectification (SR) reduce process energy consumption, while the modular 19-inch external footprint allows for scalable power levels.

Paired with the new M-1 Controller featuring digital controls, a bright LCD screen, advanced data logging, and Ethernet/IP connectivity capability, the DTX-6000 delivers superior performance and premium power. DC. 200Hz, Air cooled, 9782738100 amps, 12-100 volts, 6,000 watts. DTX-12000 also available.

Applications

Electro-Plating

Electro-Forming

Electro-Refining

Electrowinning

Anodizing

General Metal Finishing (GMF)

Dynatronix by Process Technology®

DTX-12000 Series

Powered for a better finish!

The high-performance DTX-12000 Dynatronix by Process Technology Power Supply will bring your process to the next level, delivering accurate, ultra-low ripple DC power.

Inside high-efficiency silicon carbide (SiC) components and synchronous rectification (SR) reduce process energy consumption, while the modular 19-inch external footprint allows for scalable power levels up to 120,000W.

Paired with the new M-1 Controller featuring digital controls, a bright LCD screen, advanced data logging, and Ethernet/IP connectivity capability, the DTX-12000 delivers superior performance and premium power. DC, 200Hz, Air cooled, 120-1,000 amps, 12-100 volts, 12,000 watts. DTX-6000 also available.

Applications

- Electroplating

- Electro-Refining

- Electro-Forming

- Electro-Polishing

- Electrowinning

- Plating on Plastic

- Anodizing

Dynatronix by Process Technology®

Pro Series

Customize to Your Exact Needs!

One of the most sophisticated power supplies available in the metal finishing industry today, the Pro Series offers the flexibility to be adapted to the most complex process. From sophisticated electroplating applications in the semiconductor industry to high-end nitinol electropolishing in the medical device market, the Pro Series can meet the needs of the most challenging applications. The Pro Series is a completely programmable power supply, built in a series of modules. Multiple cells, channels within those cells, and differing outputs from the channels, are available. Such flexibility allows the Pro Series power supply to be utilized for such applications as multiple cathodes, multiple or segmented anodes, and multiple plating baths. Customize to your needs! Pulse, Air cooled, XR, 0.001-50 amps, 1-350 volts.

FOR EXPERT TECHNICAL SALES

Call (978) 273-8100

Process Technology®

DE 20 Series Thermostat

Single Set - Point, Precise Control Provides precise digital control for consistent plating and etch rates in most aqueous processes. Vapor resistant. Up to 20 amps (may be lower with some heaters). Adjustable temperature range from -40°F (-40°C) to 1000°F (538°C), high temp sensor required.

Process Technology®

DE Series Relay/Control

30 amp, Single Set-Point, Precise Control

Provides precise digital control for consistent plating and etch rates in most aqueous processes. Large (.56” high), easy to read LED display. Vapor tight, IP21, front panel protection. ±.25% full span, single digit accuracy. 30 amps switching capabilities. 120-240 volts. Adjustable temperature range from -40°F (-40°C) to 1000°F (538°C).l

Process Technology®

DE Series Combination Control

9782738100 amps, Single Set-Point, Precise Control

Provides precise digital control for consistent plating and etch rates in most aqueous processes. Single or three phase. Large (.56” high), easy to read LED display. Fluoropolymer (FEP) covered 10-foot (3m), 1000-ohm platinum RTD sensor included standard with the control. Vapor resistant, NEMA 1, IP21, gasketed 1/8 DIN plastic enclosure with sealed tactile switches and stainless steel hardware. Large switching capacity from 9782738100 amps up to 600 volts. Adjustable temperature range from -40°F (-40°C) to 1000°F (538°C).

Process Technology®

DLC Series Relay/Control

Single Set-Point, 30 amps Provides precise control for consistent plating and etch rates in most aqueous processes. Large (.56” high), easy to read LED display. Fluoropolymer (FEP) covered 10-foot (3m), 1000-ohm thermistor sensor included standard with the control. Vapor tight, IP21, front panel protection, plastic enclosure with sealed tactile switches. 30 amp switching capacity for either 120 or 240 volts. Single phase. Adjustable temperature range from -58°F (-50°C) to 302°F (150°C).

Process Technology®

DQ Series Relay/Control

30 amps, Dual Set-Point, Precise Control

Provides precise control for consistent plating and etch rates in most aqueous processes. Large (.56” high), easy to read LED display. Two set points (heating and cooling). Fluoropolymer (FEP) covered 10-foot (3m), 1000-ohm platinum RTD sensor included standard with the control. Vapor resistant, NEMA 1, IP21, gasketed 1/4 DIN plastic enclosure with sealed tactile switches and stainless steel hardware. Up to 30 amps. 600 volts. Single or three phase. Adjustable temperature range from -40°F (-40°C) to 1000°F (538°C)

Process Technology®

DQ Series Thermostat

Up to 15 amps, Dual Set-Point, Precise Control

Provides precise digital control for consistent plating and etch rates in most aqueous processes. Large (.56” high), easy to read LED display. Two set points (heating and cooling). Fluoropolymer (FEP) covered 10-foot (3m), 1000-ohm platinum RTD sensor included standard with the control. Vapor resistant, NEMA 1, IP21, gasketed 1/4 DIN plastic enclosure with stainless steel hardware. Up to 15 amps. 600 volts. Single or three phase. Adjustable temperature range from -40°F (-40°C) to 1000°F (538°C)

Process Technology®

DSL Series Thermostat

Dual Set-Point, Up to 3 amps

Provides precise control for consistent plating and etch rates in most aqueous processes. .3 inch (7.6mm), dual LED displays. Fluoropolymer (FEP) covered 10-foot 3m), 1000-ohm platinum RTD sensor included standard with the control. 1/16 DIN size with NEMA 1 (indoor), IP21, 3R and 12 rated front panel and sealed tactile switches. Dual digital thermostat with heating and cooling up to 3 amps. 120-240 volts. Single phase. Adjustable temperature range from -328°F (-200°C) to 4208°F (2320°C).

Process Technology®

DSL Series Relay/Control

Dual Set-Point, 30 amps

Provides precise digital control and power relay for consistent plating and etch rates in most aqueous processes. .3 inch (7.6mm), dual LED displays. Fluoropolymer (FEP) covered 10-foot 3m), 1000-ohm platinum RTD sensor included standard with the control. NEMA 1, IP21, flame retardant and gasketed plastic enclosure with stainless steel hardware. Heating and cooling up to 30 amps. 120-240 volts. Single phase. Adjustable temperature range from -328°F (-200°C) to 4208°F (2320°C).

Process Technology®

DSL Series - Combination Control

Dual Set-Point, 9782738100 amps

Provides precise digital control for consistent plating and etch rates in most aqueous processes. Combination control features .3 inch (7.6mm), dual LED displays. Fluoropolymer (FEP) covered 10-foot 3m), 1000-ohm platinum RTD sensor included standard with the control. NEMA 1, IP21, flame retardant and gasketed plastic enclosure with stainless steel hardware. Dual setpoint with heating and cooling up to 30 amps. 120-240 volts. Single phase. Adjustable temperature range from -328°F (-200°C) to 4208°F (2320°C).

Process Technology®

DLC Series Combination Control

Single Set-Point, User Friendly Control

Provides precise digital control for consistent plating and etch rates in most aqueous processes. Large (.56” high), easy to read LED display. Fluoropolymer (FEP) covered 10-foot (3m), 1000-ohm thermistor sensor included standard with the control. NEMA 1, IP21, flame retardant and gasketed plastic enclosure with stainless steel hardware. Large switching capacity from 9782738100 amps for up to 600 volts. Single phase. Adjustable temperature range from -58°F (-50°C) to 302°F (150°C).

Process Technology®

DQ Series Combination Control

9782738100 amps, Dual Set-Point, Precise Control

Provides precise digital control for consistent plating and etch rates in most aqueous processes. Large (.56” high), easy to read LED display. Fluoropolymer (FEP) covered 10-foot (3m), 1000-ohm platinum RTD sensor included standard with the control. Vapor resistant, NEMA 1, IP21, gasketed 1/8 DIN plastic enclosure with sealed tactile switches and stainless steel hardware. Large switching capacities from 9782738100 amps up to 600 volts. Single or three phase. Adjustable temperature range from -40°F (-40°C) to 1000°F (538°C)

Process Technology®

DSL Series - Combination Control

Dual Set-Point, 9782738100 amps

Provides precise digital control for consistent plating and etch rates in most aqueous processes. Combination control features .3 inch (7.6mm), dual LED displays. Fluoropolymer (FEP) covered 10-foot 3m), 1000-ohm platinum RTD sensor included standard with the control. NEMA 1, IP21, flame retardant and gasketed plastic enclosure with stainless steel hardware. Dual setpoint with heating and cooling up to 30 amps. 120-240 volts. Single phase. Adjustable temperature range from -328°F (-200°C) to 4208°F (2320°C).

Process Technology®

DRAE Series Digital Thermostat

DRAE, Thermostat, 15 amps, 120 volts, W/Easyplug. Provides precise control for consistent temperature in aquaculture applications. Large easy to read LCD display. 8' (2.4m) vinyl sleeved sensor standard, longer sensor lengths available. Indoor use only, please contact our office for outdoor applications. cULus listed. NEMA 1, IP21, Vapor resistant plastic enclosure with sealed tactile switches. Certification: cULus.

Process Technology®

DRA Combination Control

Microprocessor- based electronic temperature control designed to provide on/off control for general aquaculture service. The DRA is equipped with a liquid crystal display (LCD) that provides a constant readout of the sensed temperature, and a touch keypad that allows the user to easily and accurately select the setpoint temperature, differential and heating/cooling mode of operation. Heating and cooling. 120 or 208/240 VAC, 50/60 Hz. Temperature range -30°F (34°C) to 220°F (104°C)

Process Technology®

LP Series Liquid Level Control

Conductive liquid level control. Provides automated control and consistent liquid levels for most aqueous processes and waste treatment tanks, or when leak detection is required. Helps protect against fires and tank damage associated with low-level conditions. Dual probe units (LC2): for single point control. Multi probe units (LC3): for two-point control.

Process Technology®

DRA Series Digital Thermostat

Aquaculture temperature control with large, easy to read LCD display. Single phase only. 120 or 240 volt power supply: 50 or 60 Hz. Adjustable temperature range from -30°F (-34°C) to 220°F (104°C). Indoor use only (Contact customer service for outdoor use information).

Process Technology®

LC Series Control

Provides automated control and consistent liquid levels for most aqueous processes and waste treatment tanks, or when leak detection is required. Helps protect against tank damage associated with low-level conditions. Product can also be used to control a valve to replenish liquid in a tank. 120 volt.

FOR EXPERT TECHNICAL SALES

Call (978) 273-8100

Process Technology®

Thermax

Compact modular design

Patented fabrication process ensures consistent, high quality production. Manifolding is simplified for larger applications. No gaskets to fail. TIG welding is used on the sheet edge (which separates Circuit A from Circuit B). Offers easy installation and servicing. Manifolding is simplified for larger applications. Heat loss is low, requiring little or no insulation. Standard unit is 316 Stainless Steel. Titanium available as an option.

Process Technology®

XC Series

Provides precise digital control for consistent plating and etch rates in most aqueous processes. Large (.56” high), easy to read LED display. Vapor tight, IP21, front panel protection. ±.25% full span, single digit accuracy. 30 amps switching capabilities. 120-240 volts. Adjustable temperature range from -40°F (-40°C) to 1000°F (538°C).l

Process Technology®

XC High-Flow

Ultra-high purity, high-flow heat exchanger

The XC inline heat exchanger is now available with a high-flow option that provides the same heat transfer performance as before but now with a reduced fluid pressure drop. With a PFA tube-side fluid path the XC Series will meet the most stringent cleanliness requirements to support next-generation ultra-high-purity (UHP) semiconductor node technologies. This exchanger supports both recirculating and single pass flow applications. Heats up to 275°F (135°C)

Process Technology®

X Series Coil

Robust Design

Eliminates stray currents in tanks. Excellent chemical compatibility and rugged design for your heating or cooling application. All wetted parts of fluoropolymer (FEP, PFA or PTFE) construction with a heavy duty CPVC mounting bracket. Standard coils are FEP and rated up to 30 PSI steam service. PFA coils are available for steam service up to 60 PSI. 10 PSI minimum steam pressure required for operation. Heavy wall tubing improves circulations and reduces pressure drop. Heavy duty CPVC mounting bracket and 1/8-inch thick perforated guard helps protect the coil from damage. Integral inlet/outlet connections reduce potential for leaks. 10 PSI minimum steam pressure required for operation.

CALL NOW FOR EXPERT TECHNICAL SALE ASSISTANCE

(RAPID RESPONSE)

We're ready to assist you. We can identify, size and spec your pumps, filters, coils, heaters, power supply equipment and more. Let us find the exact replacement item, and troubleshoot your pump and processing problems.